Your basket is currently empty!

Discover our selection

James Heal have the technical experience and knowledge to understand the crucial importance of compliant test materials to the end user

About us

For over 150 years James Heal has been providing innovative testing solutions to the textiles industry.

Shipping and delivery information

If you have any enquiries or questions, please email:

- Accessories/Spares

- Consumables

- Instrument

- Sample cutters

- AATCC Test materials

- Blue wool standards

- Bursting strength test materials

- Crocking cloth & cotton lawn

- Detergents

- Grey scales

- Makeweights

- Martindale test materials

- Multifibre DW/LW

- Phenolic yellowing

- Photographic standards

- Pilling/snagging materials

- Certificate

Shipping and delivery information

If you have any enquiries or questions, please email:

- UK: [email protected]

- USA, Canada and Puerto Rico: [email protected]

FAQs

Frequently asked questions about James Heal’s range of pre-prepared test materials.

Martindale test material

The test materials required to meet ISO 12947 are listed below. James Heal can provide all of these Test Materials.

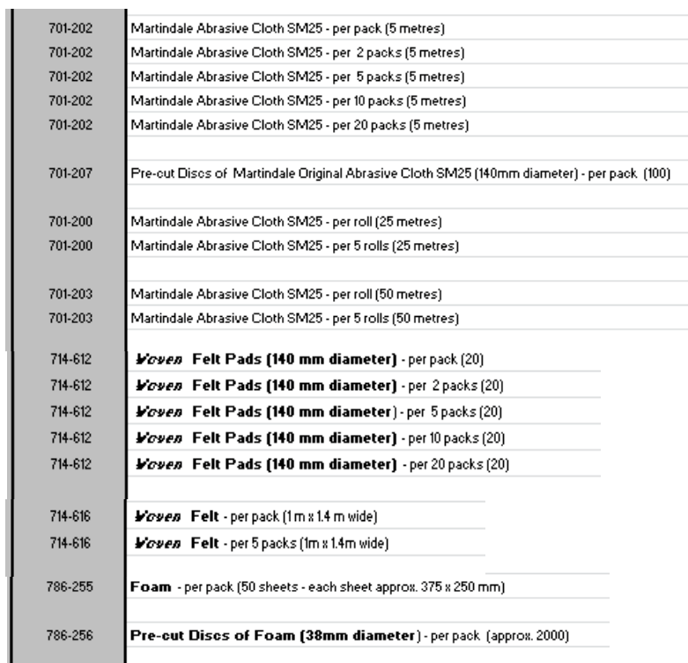

SM25:

- Available as a pack of 100 x 140mm diameter discs.

- Available as a 5m piece.

- Available as a 25m roll.

- Available as a 50m roll.

Polyurethene Foam :

- Available as a pack of 2000 x 38mm diameter discs.

- Available as a pack 50 sheets 375mm x 250mm.

Woven Felt:

- Available as a pack 20 x 140mm diameter discs.

- Available as a piece 1m x 1.4m.

STFI is a German association which produces STFI abrasive fabric. This abrasive fabric complies with DIN ISO 12947, amongst other standards. James Heal’s SM25 also complies with DIN ISO 12947, the two products are equivalent of each other.

James Heal’s SM25 can be used as a substitute abrasive fabric unless the standard does not allow it and states that STFI must be used.

James Heal is unable to supply STFI abrasive fabric as the manufacturer only sells directly to customers.

The 3 tables below display the property requirements for all test materials specified in ISO 12947-1 Determination of the abrasion resistance of fabrics by the Martindale method – Part 1: Martindale abrasion t

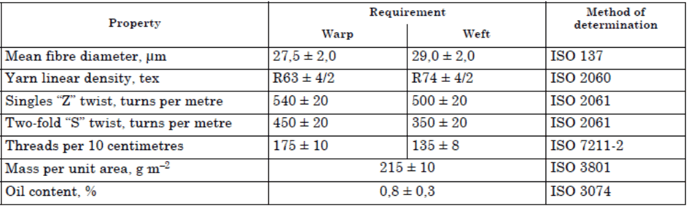

Table 1 – Property requirements for wool abradant fabric:

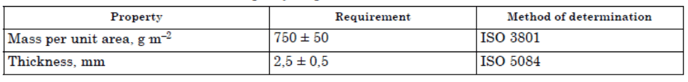

Table 2 – Property requirements for woven wool felt:

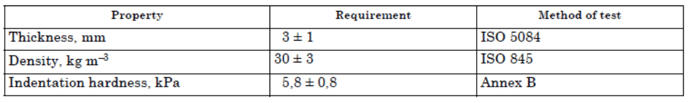

Table 3 – Property requirements for polyetherurethane foam

Below is a list of compliant items from James Heal:

James Heal’s SM25 can be used as a substitute abrasive fabric unless the standard does not allow it and states that STFI must be used.

James Heal is unable to supply STFI abrasive fabric as the manufacturer only sells directly to customers.

Foam should not be used if it has started to discolour. The below information explains why not.

Why not?

A polymer consists of many molecules strung together by links to form a very long chain.

Polyurethane is a polymer composed of organic units joined by urethane links.

Polyurethane foam will discolour if an amine forms instead of a urethane link. This amine can become oxidised to a quinone. Quinones are yellow and so cause the discolouration.

There are 3 main reasons why an Oxidation Reaction can occur:

- Exposure to Light

- Exposure to Gas – oxides of nitrogen from motor emissions, gas furnaces etc will cause foam to become oxidised.

- Heat Exposure – The reaction involved in the foam making process is exothermic (produces heat). If an elevated temperature is reached and maintained the foam can become scorched in the centre. As it cools, it draws oxygen inside which then causes the same oxidation reaction. Exposure to heat as a finished product can also cause discolouration.

- Exposure to BHT – BHT (Butylated hydroxyl toluene) is a widely used antioxidant in many plastics. It is very volatile and can leave a deposit on other materials such as polyurethane foam even without direct contact. In the correct conditions BHT will oxidise, forming chromophores which turn the polyurethane foam yellow.

Foam should not be used if it has started to discolour. Discolouration is the first step in degradation, which is permanent and irreversible.* The links or bonds may have already started to break as the polymer becomes more oxidised, resulting in the foam being brittle and unsuitable for use. The foam will ultimately degrade.

Storage

In a laboratory environment the most likely causes would be exposure to UV Light and Heat. Foam should be stored in the dark at room temperature to avoid exposure. Foam should be stored in these conditions for a maximum of 24 months unopened, and 12 months once opened.

*Discoloration from BHT exposure is reversible by treating with an acidic rinse but is not recommended by James Heal when carrying out Martindale Abrasion Testing.

Cotton lawn / Crocking cloth

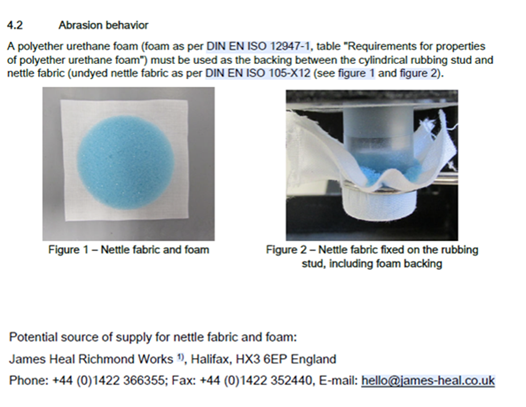

TL 226 and PV 3906 are carried out on CrockMaster. These standards specify to use nettle fabric as per DIN EN ISO 105-X12.

DIN EN ISO 105-X12 is an adoption of EN ISO 105-X12, which specifies the use of a ‘cotton rubbing cloth,’ the specification for which can be found in EN ISO-F09. There is no inclusion of the term ‘nettle fabric’ in either standard.

It would appear that there has been a mis-translation in TL 226 and PV 3906, and that the term ‘nettle fabric’ appears in these standards in place of the term ‘crocking cloth.’

James Heal supplies crocking cloth for these standards as a pack of 500, 5cm x 5cm pieces, under stock code 702-540.

ISO 105-F09 is not a test procedure. It does not give any test method details.

ISO 105-F09 – Specification for cotton rubbing cloth, specifies the properties that the cloth must possess for compliance with all ISO colour fastness tests where required, which includes ISO 105 X12 – Colour fastness to rubbing.

James Heal can supply this material in piece form, or in convenient pre-cut pieces. Pre-cut pieces can be ordered with either straight or gimped edges.

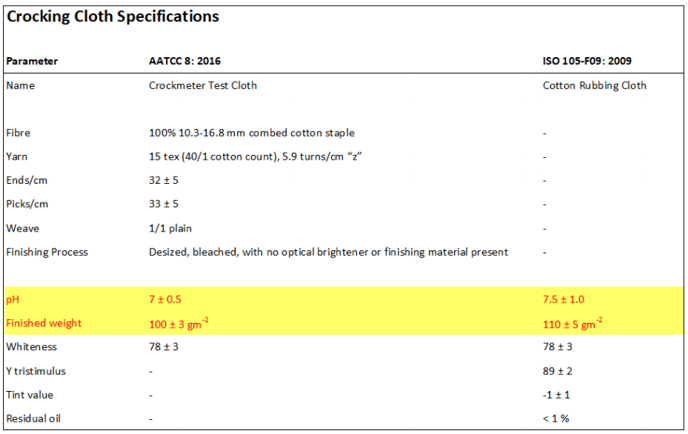

There are two specifications, the notable differences being the pH of aqueous extract and mass per unit area (Finished Weight). ISO crock test cloth results may not be equivalent to AATCC crocking cloth results/values based on crocking cloth study.

Photographic standards

The Marks & Spencer Stay New Photographs which are used in M&S P144 series of test methods are not available from James Heal, they are only available from UL in the UK. Here are their contact details:

UL VS Ltd

530/535 Eskdale Road

Reading, RG41 5TS, UK

Tel: +44 (0) 118 927 3340

Fax: + 44 (0) 118 927 3341

M&S Photographic standards:

Ref: J : Photographs: Numbers 1 to 5 for Knitted Jersey

Ref: K : Photographs: Numbers 1 to 5 for Knitwear

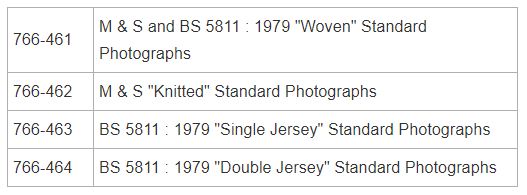

BS 5811 is an obsolete method. ISO 12945-1 is the replacement standard. The BS 5811 standard reference photographs can continue to be used to aid assessment.

They can be purchased from James Heal:

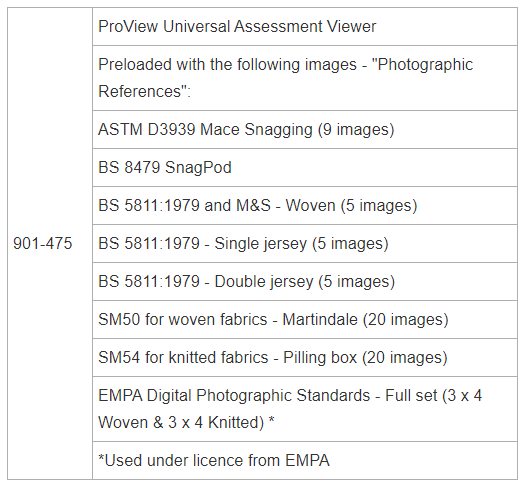

Alternatively, these photographic standards along with those in the list below are available electronically on James Heal ProView.

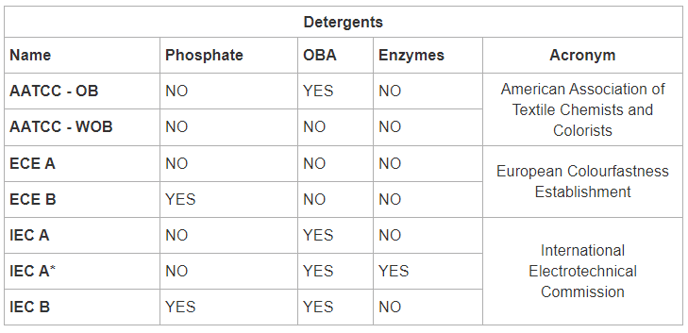

Detergents

Sodium perborate is added to detergents as its oxidative power improves cleaning, bleaching and stain removal performance of the detergents.

It reacts with water in the wash test and releases oxygen at elevated temperatures >60°C and so acts as a hydrogen peroxide bleach.

It can be used at lower temperatures if used in conjunction with TAED – a bleach activator. This activates the hydrogen peroxide and generates paracetic acid. This is a faster and more efficient bleach at temperatures below 60°C.

Sodium Perborate and TAED are classed as unstable and so are not suitable to be premixed with detergents.

Also not all wash tests specify to use Sodium Perborate or TAED, so having them already in the detergent would render the detergent unsuitable.

James Heal is able to supply TAED as either a 250g container (706-735) or a 500g container (706-743).

James Heal is unable to supply Sodium Perborate as it is classed as hazardous.

The following detergents contain phosphates: – ECE B – IEC B

The following detergents do not contain phosphates:

- AATCC – OB

- AATCC – WOB

- ECE A

- IEC A

- IEC A*

Although all detergents should be kept in a tightly closed container and stored in a cool dry place, this is even more essential for detergents which contain phosphates.

These types of detergents are more prone to biological degradation under moist conditions than those detergents which are phosphate free.

The following detergents are OBA free: – AATCC – WOB – ECE A – ECE B

The following detergents contain OBA :

- AATCC – OB

- IEC A

- IEC A*

- IEC B

Once received by end user… – Unopened: 18 months – Opened: 6 months

- We are often asked about the shelf life of these products because of the critical testing and colour fastness applications in which they are used

- For unopened and undamaged containers, it is 18 months

- Once opened, the container must be tightly closed and stored in cool and dry conditions. Dispose of the remainder after 6 months according to local Regulations

- When decanting the product from the container use only clean and dry implements, such as scoops, spatulas, etc. Replace the cover immediately and ensure it is sealed fully and correctly

- It should be accepted that this is a product designed to a specification set down in International Standards and is intended for testing purposes only. As such, the product contains no preservatives. In addition, some of the ingredients are prone to absorb moisture from the surrounding atmosphere. This will not only reduce the excellent flow properties of the powder but may reduce the stability of the compound by initiating the biodegradation process. The active weight of the product will also be reduced if moisture is absorbed

- With the exception of IEC(A*), the products contain no enzymes, i.e., they are not “biological” detergent products IEC(A*) contains a protease enzyme

- The “phosphate” containing detergents are more prone to biological degradation under moist conditions than the phosphate free types

- Solutions of the detergent are not stable for more than a few hours and should be freshly made immediately before required for testing

- Products and solutions containing “optical brightening agent” should be stored away from light (in darkness)

- Solutions containing sodium perborate have very limited stability due to decomposition of the peroxy compound

- Additions of oxygen-active compounds should be made immediately prior to testing

- This information does not replace the Materials Safety Data Sheet

The below table shows which detergents contain OBA, Phosphates or enzymes.

James Heal cannot currently supply the detergents specified in ISO 15797 and ISO 105-C12.

EN ISO 15797:2004

Textiles. Industrial washing and finishing procedures for testing of workwear

EN ISO 105-C12:2006

James Heal Reference Detergents can be classified into two generic types: – IEC or ECE type “A” – IEC or ECE type “B”

The following ecological data are estimated on the basis of the raw materials contained in the product and/or of structurally comparable substances.

The surface active agents (surfactants) contained in the products are in the mean degradable by at least 90%.

Type A

In tests for ready degradability (e.g., OECD 301 A-F) the total organic products contained in the product achieved values below 60 % BOD/COD and 70 % DOC reduction.

Type B

The sum of the organic components of the product reach a degradability of approximately 60 %

BOD/COD and about 70 % DOC-reduction.

The limits for classification as “easily degradable/readily degradable” are at least 70 % DOCreduction and at least 60 % BOD/COD within 28 days.

Therefore, we can say that Type A Reference Detergents cannot be classified as readily degradable.

However, Type B Reference Detergents are just within the limits of classification and can be described as readily degradable.

Wascator FOM 71 CLS is a type A, Automatic Washing Machine. Only Reference Detergents 2 (IEC A*), 3 (ECE A) and 6 (IEC A) should be used. These will be referred to as Detergent Base Powders for the purpose of this document.

A total of 20g of detergent should be used, NOT 100g as is sometimes mistakenly used.

The 20g is made up of three components:

- Detergent Base Powder

- Sodium Perborate Tetrahydrate

- Tetra-Acetylethylene (TAED)

These should be dry mixed throughly before adding to the dispenser.

These components should be used in the following proportions:

- Detergent Base Powder 77 parts/percent (15.4g)

- Sodium Perborate Tetrahydrate 20 parts/percent (4g)

- TAED 3 parts/percent (0.6g)

Once dry mixed, the detergent should be used immediately.

If this is not possible, mixed detergent may be kept in a sealed container for a maximum of 14 days, provided this does not contradict the expiry dates on the individual components.

TAED and sodium perborate are not contained within the detergent base powder. They must be bought and stored separately and added to the wash test at time of testing.

TAED and sodium perborate are classed as unstable. If they were already added to the detergent, this would have a detrimental effect on the detergent, rendering it unusable.

Weighing these out at the time of testing ensures that they are added to the test in accurate amounts.

James Heal can supply TAED as a 250g container 706-735, or as a 500g container 706-433.

James Heal is unable to supply Sodium Perborate.

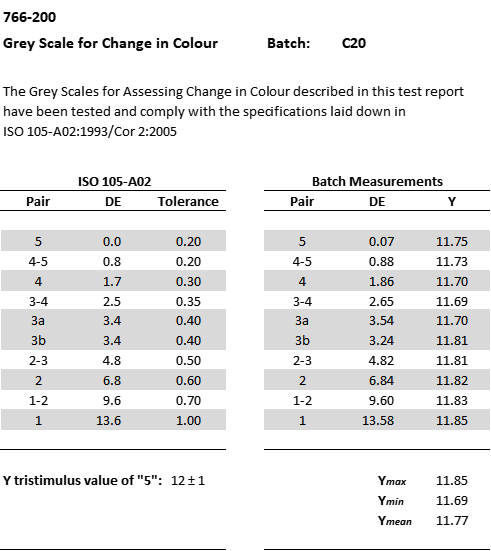

Certificates of conformity

Test Report and Certificate of Conformity

The below PDF shows how to locate all the Certificates of Conformity.

Test Report and Certificate of Conformity

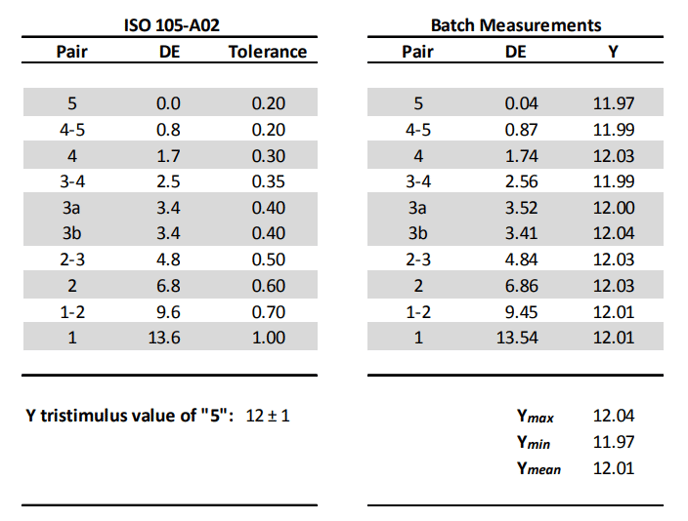

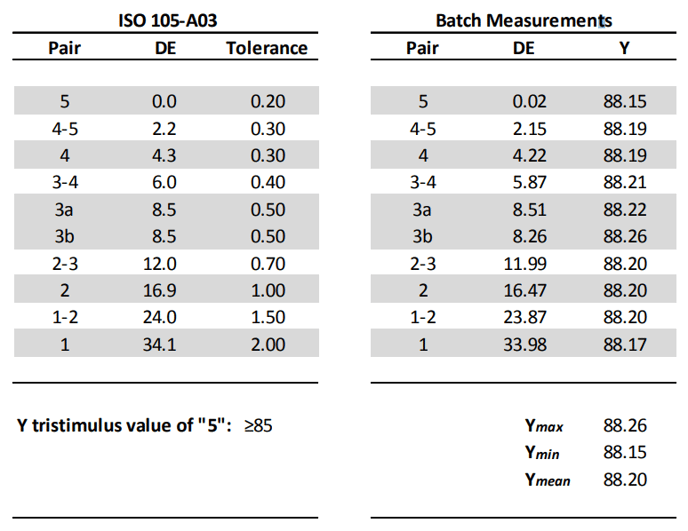

Test Report and Certificate of Conformity for James Heal Grey Scale for Change in Colour

766-200

Grey Scale for Change in Colour Batch: C18

The Grey Scales for Assessing Change in Colour described in this test report

have been tested and comply with the specifications laid down in

ISO 105-A02:1993/Cor 2:2005

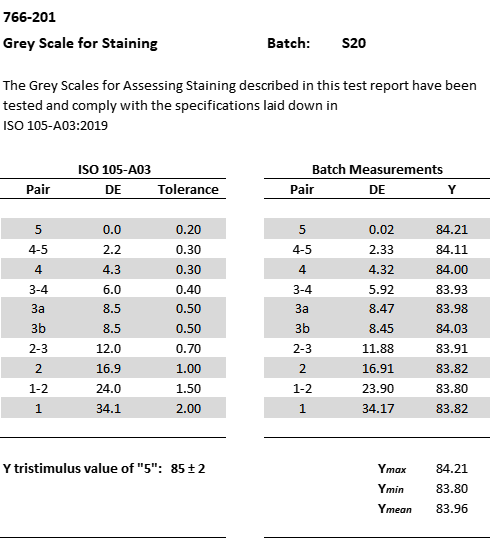

Test Report and Certificate of Conformity for James Heal Grey Scale for Staining

766-201

Grey Scale for Staining Batch: S18

The Grey Scales for Assessing Staining described in this test report have been

tested and comply with the specifications laid down in

ISO 105-A03:1993/Cor 2:2005

MultiFibre

New users of Multifibre adjacent fabric often ask which end of the Multifibre should be sewn to the specimen.The attached FAQ gives an example when preparing a fabric specimen.

Both products are manufactured on site at James Heal and go through stringent quality control checks at numerous points in the manufacturing process.

Multifibre DW complies with ISO 105-F10.

It consists of individual strips of the following components:

- Diacetate

- Bleached Cotton

- Polyamide

- Polyester

- Acrylic

- Wool

Multifibre LW is approved by Marks & Spencer and complies with C3.

It consists of individual strips of the following components:

- Regenerated Cellulose

- Bleached Cotton

- Polyamide

- Polyester

- Acrylic

- Wool

The difference is in strip 1 – Multifibre LW contains regenerated cellulose instead of diacetate as it is considered to have more relevance to fibres used in modern apparel fabrics.

To aid identification between the two, Multifibre LW has a black thread in the selvedge.

The yarn used for this strip has been thoroughly tested for colour fastness.

The Chinese Standard GB 11404 -1989 Textiles – Test for colour fastness – Specification for standard adjacent fabric: Multifibre – is now obsolete.

It has been superseded by GB/T 7568.7, which is based on ISO 105-F10.

GB/T 7568.7-2008 states that the types of multifibre accompanying fabric were changed.

Multifibre SW is replaced by Multifibre DW.

This is available from James Heal either as a roll of various lengths or as pre-cut pieces with gimped edges.

Multifibre SV is replaced by Multifibre TV – also known as American Style 41.

This is available from James Heal as a roll of various lengths or as precut pieces with straight edges.

Blue wool references

Blue Wool References are not correlated against actual daylight exposure. This is because real conditions vary.

It is not just the light that needs taking into consideration, but the temperature and humidity also.

As an example, we can say that if the irradiance is controlled at 42W/m² (300 – 400nm):

- Blue Wool 5 will fade to a grey scale 4 in approximately 80 hours

- Blue Wool 6 will fade to a grey scale 4 in approximately 160 hours

Blue Wool References are designed to fade in a geometric progression, each successive reference taking twice as long to fade to the same grade as its predecessor, e.g. a fabric with a colour fastness to light of 6 is twice as good as a fabric which has colour fastness to light of 5.

James Heal Blue Wools are made in Germany and originate from DEK – The German Colour Fastness Commission. DEK hold the global master standards.

Every batch of Blue Wools 1-7 is rigorously tested for conformance against ISO 105 – B08.

These tests are:

- Instrumented assessment of evenness of the dye

- Instrumented and visual assessment of the fading characteristics

Blue Wool 8 is not suitable to be tested in this way as the time taken to fade to a grade 3 and 4 would be too great and not time effective.

A more efficient method for Blue Wool 8 is currently being devised.

If properly stored, these test materials can be used for at least two years in an unrestricted standard-compliant manner for determining and evaluating colour fastness to light and weathering.

Proper storage means: In the original packaging and in a dry, dark place – in any event, protected from direct sunlight and as cool as possible, but in no event at a temperature above 25°C. In an environment free of chemicals and air pollutants.

With the blue wool light fastness standards, it is particularly important that measures are consistently taken to protect them from unintentional exposure to daylight and/or artificial light. When not in use, these should therefore always be stored between the black sun protection boards and, if possible, any exposure to light that is not related to the actual test should be avoided.

There are two types of Blue Wool References: “ISO” and “AATCC”.

ISO Blue Wools

The ISO blue wools are each dyed with a different dye giving rise to light fastness scale which is an approximate geometric progression, ranging from 1 to 8. The full range of ISO blue references is currently available.

ISO 105-B02 typical conditions: 42 W/m2 (300 – 400 nm)*, 50°C BST, 40% effective humidity (use red azoic fabric to determine).

*(The SolarSens used with TruFade has one light sensor, referred to as the 300 – 400 nanometre broadband sensor).

BW1 fades to grey scale 4 in approx. 6 hours

BW4 fades to grey scale 4 in approx. 48 hours

BW5 fades to grey scale 4 in approx. 80 hours

Some of the ISO methods use a first break and second break – if second break is required then fading is continued further until grey scale 3 is achieved (this takes the same time again as it did to get to grey scale 4).

AATCC Blue Wools

The AATCC blue wools are produced from two dyed wool batches, one batch has a very low light fastness dye and the other a very high light fastness, the two batches are then blended together in different proportions to give the range L2 to L9.

Currently, due to problems sourcing the dyestuff (H&S reasons) , L9 (high light fastness) cannot be produced. As a result only L2 is currently available.

AATCC 16.3 typical conditions: 48 W/m2 (300 – 400nm), 63°C BPT, 30% relative humidity.

L2 fades to grey scale 2-3 in 20 AFU (American Fading Units), which is approximately 20 ± 2 hours under the above conditions.

Grey scales

Yes, the ISO Grey Scales that James Heal provide are compliant with GB-T standards.

- The GB-T 250 standard is based on ISO 105-A02.

- The GB-T 251 standard is based on ISO 105-A03.

To order (stock code):

- ISO 105-A02 Assessing change in colour (766-200)

- ISO 105-A03 Assessing Staining (766-201)

Grey Scales are used for assessing Change in Colour, and Staining.

The correct lighting for assessing colour change and staining is D65.

The LED currently installed in ProView is simulated Cool White.

This is correct for the assessment for pilling and snagging.

Presently there is not an interchangeable bulb setting on ProView and so assessment of Change in Colour and Staining would not be possible.

James Heal is currently looking into the possibility of an interchangeable bulb.

James Heal supplies assessment masks for the following methods: – ISO / AATCC (766-477) – M&S (766-478)

There are similarities between the 2 masks:

- Size – 228mm long and 58mm wide

- Viewing windows – 32mm x 28mm and 15mm x 50mm

- Matt black on both sides

There are 2 physical differences between the masks:

- ISO / AATCC is 0.8mm thick and is made from a single layer of flexible plastic

- M & S is 1.9mm thick and is laminated

The main differences are how these masks should be used.

ISO / AATCC

The 32mm x 28mm mask is used for assessing crocking cloth staining, or when a larger area is needed.

The 15mm x 50mm mask is used for assessing both staining and change in colour.

M&S

The 32mm x 28mm mask is for assessing change in colour.

The 15mm x 50mm mask is for assessing level of staining.

The size of the window allows for isolated from the surrounding fabric.

Makeweights

Makeweights can become stained through washing with coloured specimens. It does not have a detrimental effect on the makeweight in terms of performance.

However, they can look unsightly, and depending on the specimens being tested there is a risk of cross staining between testing.

For example: makeweights washed with dark specimens such as black or navy may absorb some of this dye. If they are then if put to wash with pale specimens, such as white or cream, some of the dark dye may be transferred onto the pale specimens. This could render the test invalid, if colour change was being assessed.

It is recommended that the user establishes different sets of makeweights to be used in wash tests:

- A set for dark coloured loads – black , navy, crimson etc.

- A set for medium coloured loads – red, blue, green etc.

- A set for light coloured loads – pale pink, white etc.

By always using the correct set for the specimens, whilst the makeweights will still become stained the risk of cross staining between specimens is greatly reduced.

Alternatively it is possible to carry out a Reduction Clear on Polyester Makeweights using Sodium Carbonate and Sodium Dithionate.

This procedure will over time damage the polyester and so repeated treatments will have a detrimental effect.

James Heal does not recommend that this procedure is followed.

James Heal will not advise further on this procedure or be held responsible for any damage caused.

James Heal offer 100% Polyester Type lII ballast /makeweights for these tests, as this is a much more economical and durable product.

ISO 6330 Section 9.3 – Selection of ballast

This section of the standard states that when testing synthetic products or synthetic blends, either Type II or Type III can be used.

- Type II ballast / makeweights: 50% Cotton / 50% Polyester

- Type III ballast / makeweights: 100% Polyester

Type l 100% cotton ballast is also available from James Heal.

Phenolic yellowing

Yellowing Papers Unopened packets have a shelf life of 2 years. Once opened, the papers can be used for 6 months providing that the packet has been kept sealed between tests.

Control Fabric

Unopened packets have a shelf life of 1 year.

Once opened, the control fabric can be used for 6 months providing that the packet has been kept sealed between tests.

BHT-free Film

Unopened boxes kept sealed and in a dark place have a shelf life of 1 year.

Once opened, the film has a shelf life of 1 year providing that the box has been kept closed and stored in the dark.

James Heal strongly recommends that consumables which have exceeded their shelf life should not be used and should be discarded.

Results obtained by using expired consumables cannot be considered valid.

This is a simple, relatively low cost, predictive test to assess the potential of white or pastel-coloured yarns, fabrics or garments to yellow in transit or in storage.

The PDF explains the causes and solutions as well as a summary of the test method.

Pilling / snagging

The pilling tubes are packaged with a leaflet recommending that pilling tubes are replaced every 2 years, or after 5000 hours of use, whichever is the soonest.

James Heal pilling tubes comply with ISO 12945-1 Textiles – determination of fabric propensity to pilling – part 1: Pilling box method. A certificate of conformity is also available.

Over time, the pilling tubes will become hard and brittle as they lose the plasticiser.

They are individually serial numbered to ensure that their usage is monitored.

They should be regularly inspected for signs of damage or wear and discarded before the recommendation if necessary.

The following James Heal products are compliant with these standards:

- Orbitor – Available as a 2 or 4 stationed instrument

- Pilling Boxes – These are universal and will fit any model of Orbitor or older James Heal Pilling Tester instrument

- White 19mm wide PVC tape

- Specimen mounting Jig

The following James Heal products are not compliant with these standards:

- Cork Liners

- Snagging Boxes

- Pilling Tubes

- Snag Pins

- Specimen Templates